Project Detail :

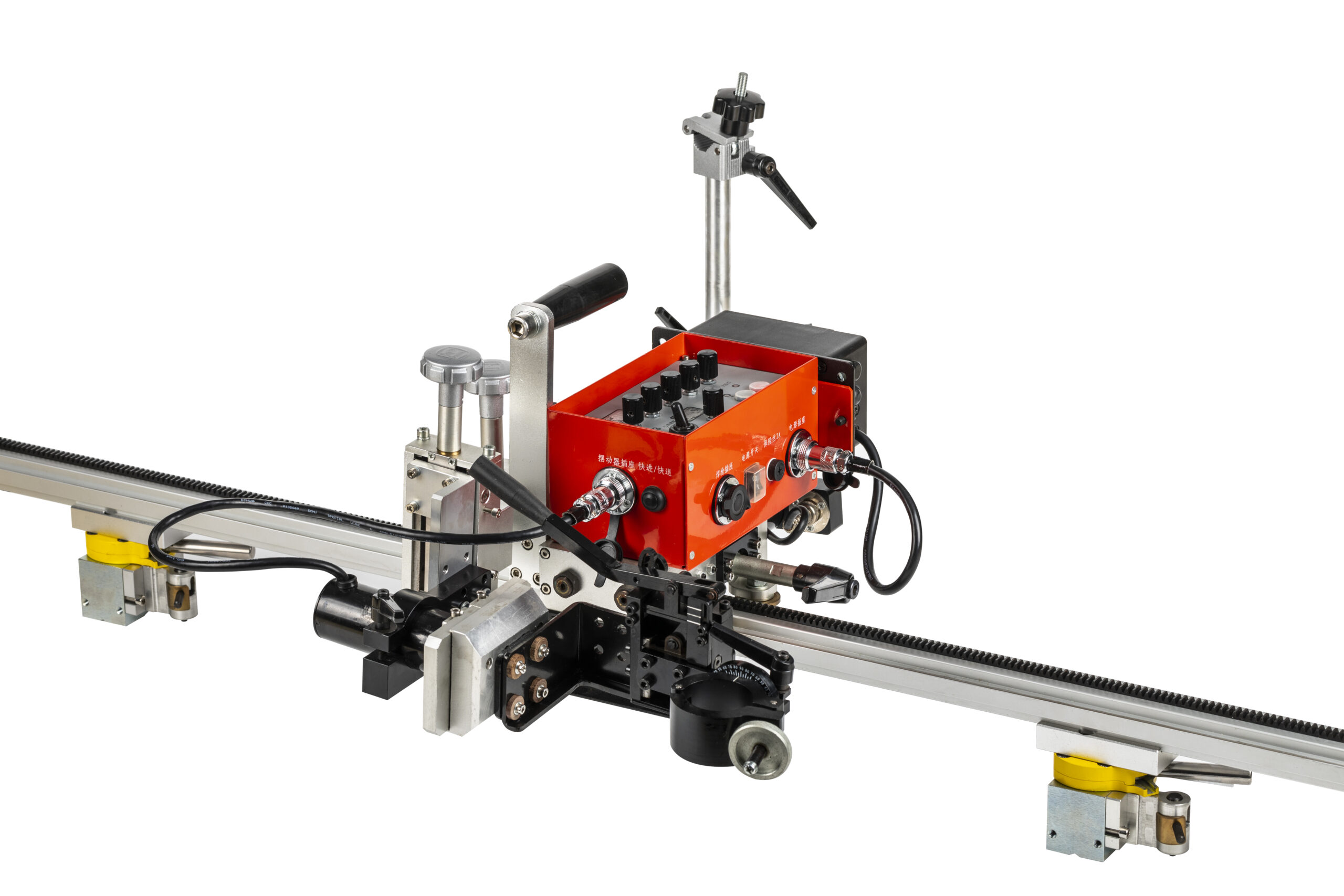

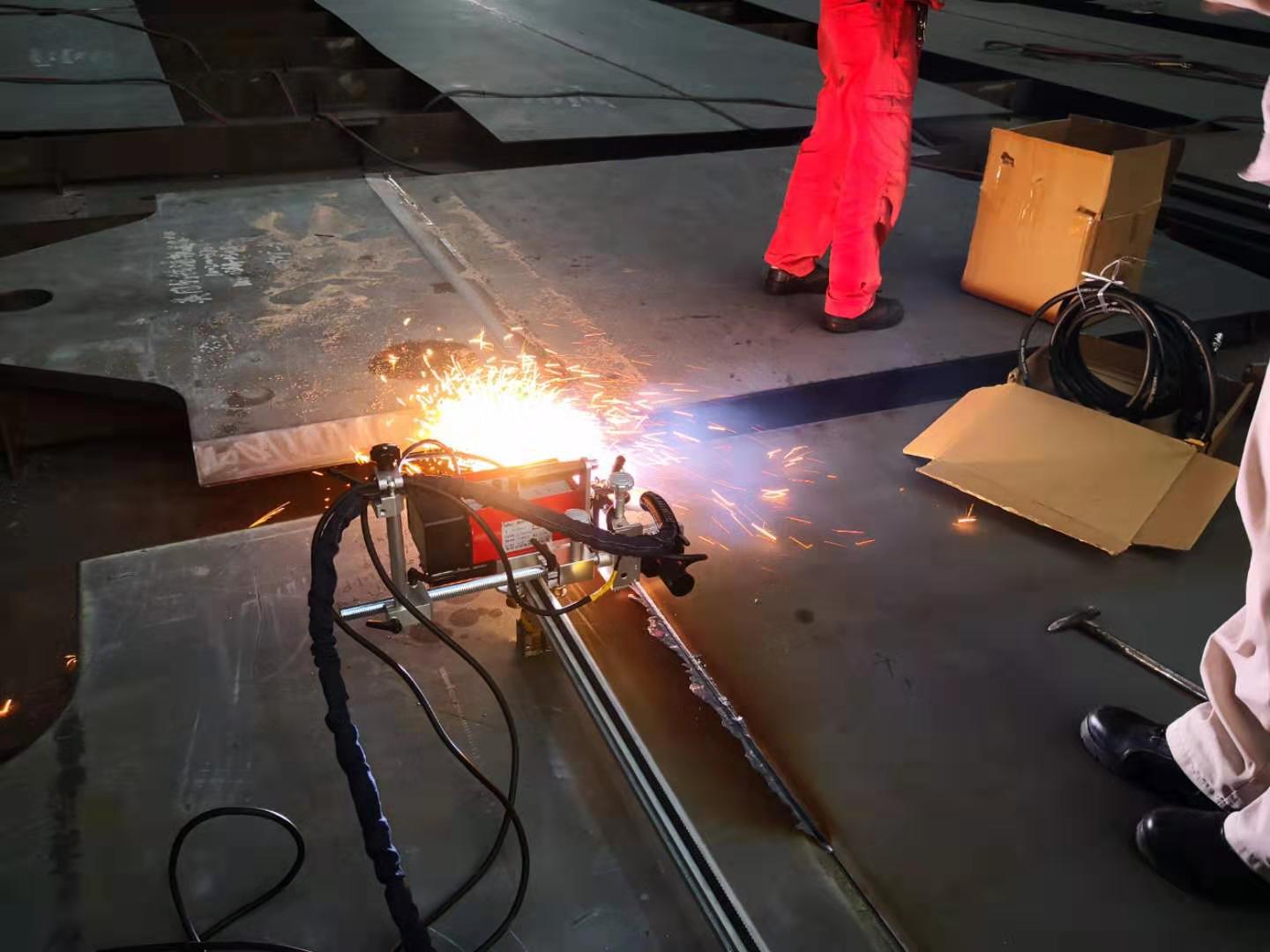

GCD400-3 - AUTOMATIC RAIL WALKING GOUGING CUTTING CARRIAGE

- Working with the plasma power supply, this carriage can complete the gouging and groove cutting operations, it greatly reduces the labor intensity.

- This carriage is using rail magnet adsorption, it completes straight walking through the rack and pinion transmission

- The rail fixed switch magnetic seat is a strong magnetic adsorption structure, the position is adjustable and it can meet the spanning installation of the reserved hole on the steel plate.

- Powered by a lithium battery, no external power supply is required, one charge can meet 10 hours of continuous operation.

- Using linear oscillator design, it can satisfied the seam gouging at different widths.

- The rail length is 1.5 meters, the continuous operation can be extended alternately through multiple rails.

Project Detail :

IHCD500-1K - BATTERY WEAVING AUTOMATIC WELDING CARRIAGE

- The whole body is made of aluminum alloy, which is solid and durable. Carriage is powered by a lithium battery, no external power supply is required, one charge can meet 8 hours of continuous operation.

- This carriage has a magnetic adsorption clutch handle and it is easy to adiust and install.

- This carriage is equipped with an oscillator part and the oscillator is driven by a brush-less motor with high precision and long using life.

- By means of magnet adsorption and the guide wheel profiling walking, it meets ordinary flat fillet welding and thick plate groove multi-pass welding.

- With welding torch arc suppression function, arc suppression time adjustment range is 0-2.5 seconds

- Fitted with rail and hook wheels, it can complete the flat butt weaving welding.

Project Detail :

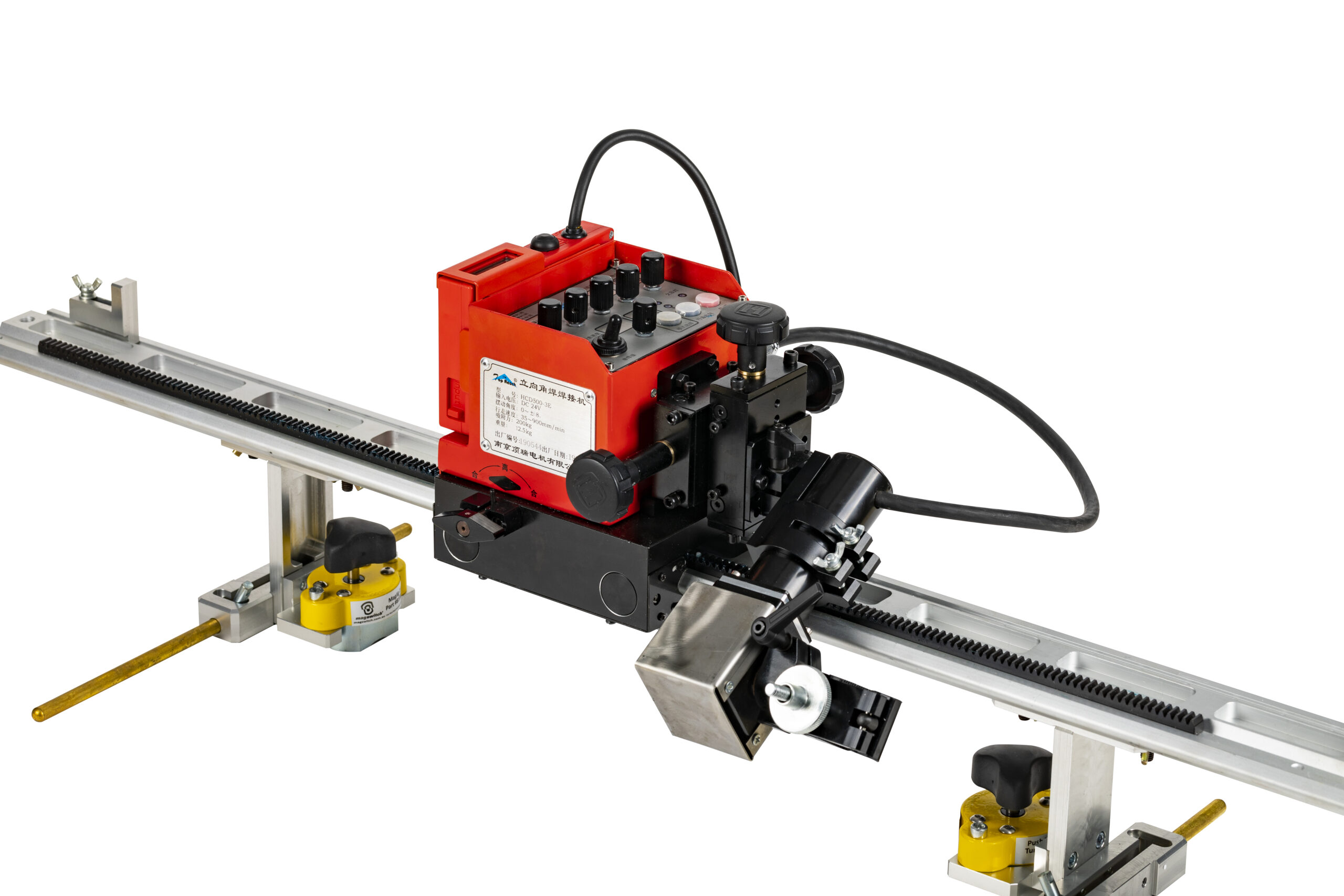

HCD500-2J - Semi-Automatic Welding Carriage

- Equipped with a conventional gas shielded welding power source, it can realize automatic submerged arc welding operation. Suitable for horizontal butt submerged arc welding.

- Realization of submerged arc welding process with gas shielded welding power supply, it is more economical and also reliable on quality.

- Powered by a lithium battery, no external power supply is required, one charge can meet 10 hours of continuous operation.

- The control panel has digital display and easy to operate. Welding gun can be adjusted in multi-angles.

- Using of the digital control system is based on MCU, it is high in control precision. The parameter visualization design is convenient for later process parameter standardization.

- Driven by full brush-less motor, it is reliable on operation and has longer using life.

- It has automatic fix synchronous laying and recycling device, efficient and convenient.

- Using two power supply and two welding torches, it is further double the work efficiency.

- Using a strong switching magnet adsorption device which is reliable easy to install.

Project Detail :

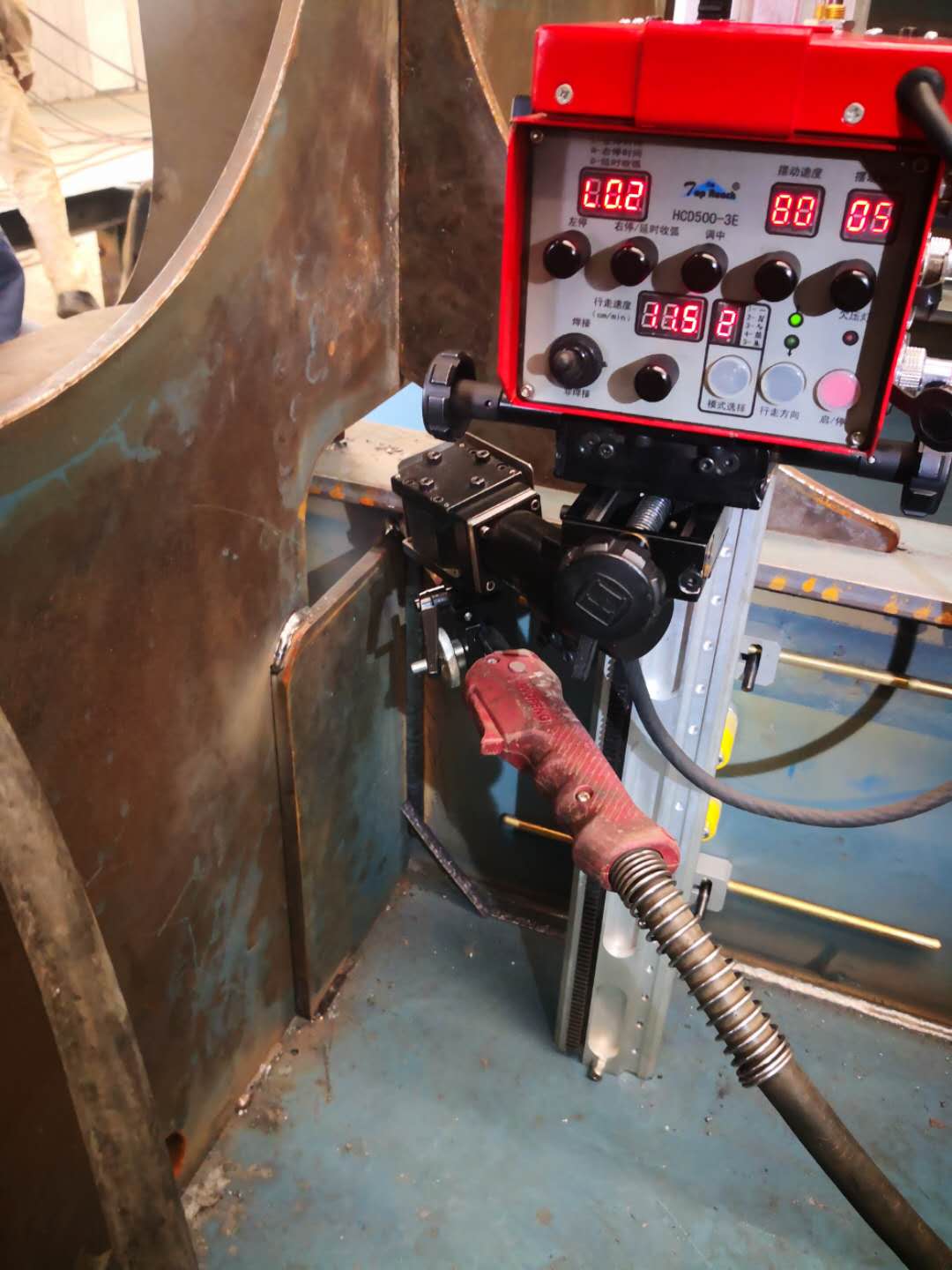

HCD500-3E - VERTICAL FILLET AUTOMATIC WELDING CARRIAGE

Equipped with a conventional gas shielded welding power source, it can realize automatic gas shielded welding operation. This carriage is especially suitable for vertical T-bar automatic welding operation.

Powered by a lithium battery, no external power supply is required, one charge can meet 8 hours of continuous operation.

Using of the digital control system is based on

MCU, it is high in control precision. The parameter visualization design is convenient for later process parameter standardization.

Driven by full brush-less motor, it is reliable on operation and has longer using life.

Using of the self-adsorbing rail special designed for T-bar, it is reliable, convenient and high efficiency.

Can choice the left or right position of the welding torch

Project Detail :

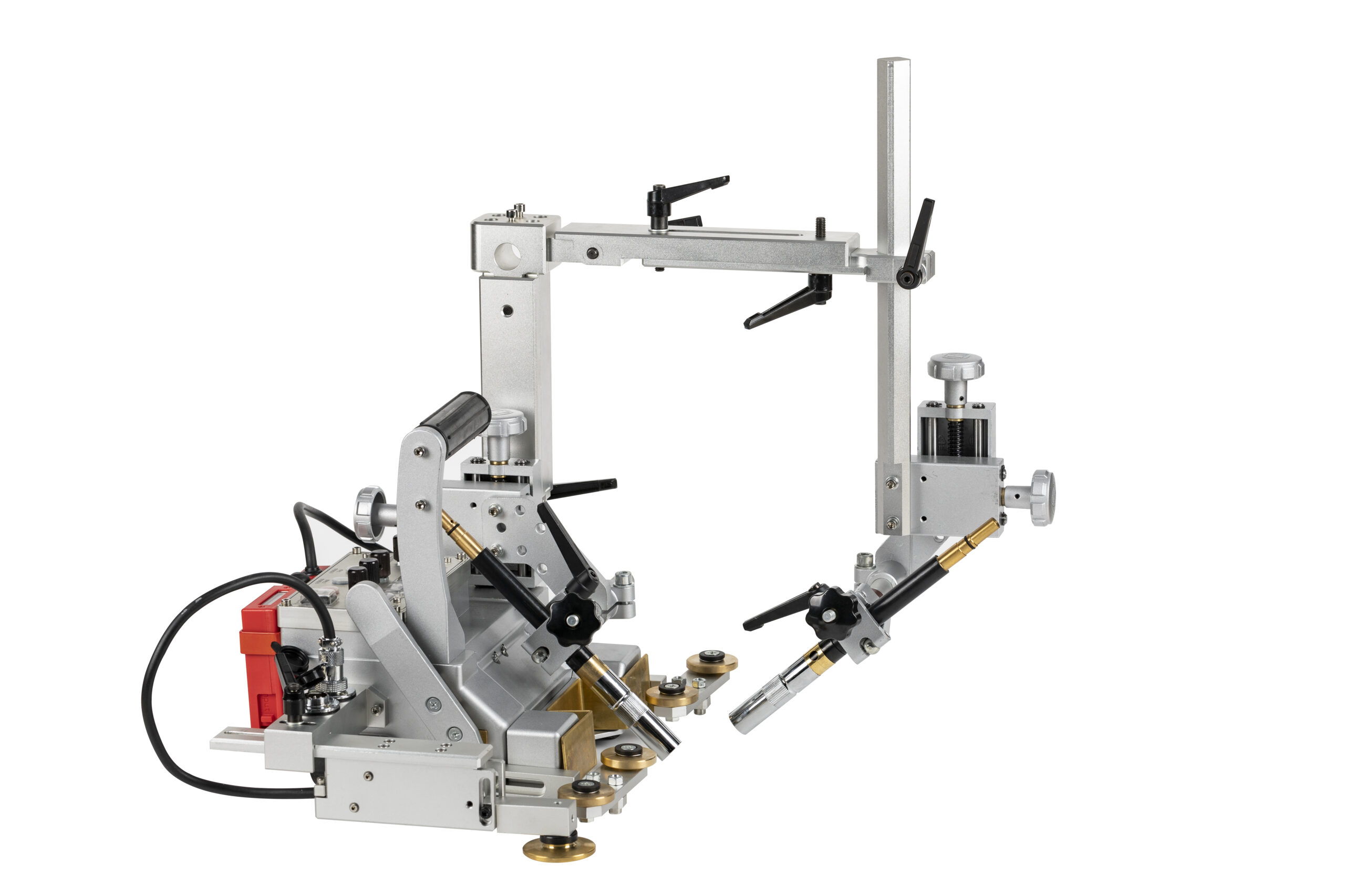

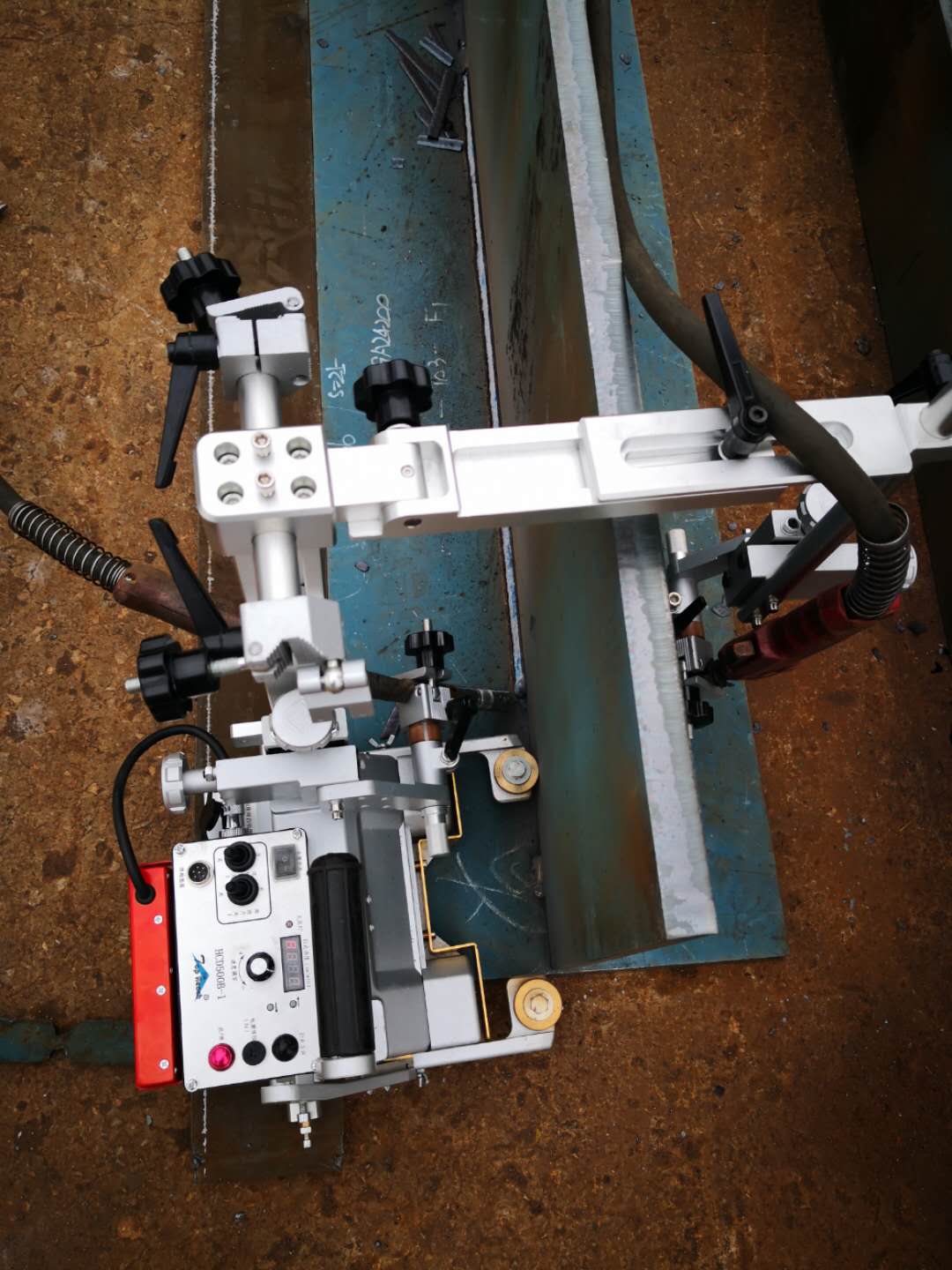

HCD500B-1 Battery Double-Side Fillet Automatic Welding Carriage

One machine holds two welding torches, one-time walking double-sided fillet welding.

It has limit stop function and one worker can operate multiple units at the same time.

This carriage has a magnetic adsorption clutch handle and it is easy to adjust and install.

Suitable for I-beam, reinforced ribs, T-beam work piece welding.

Conventional configuration for welding of ribs below 390mm height.

AC220V transformer can be configured for power supply. The model is HCD-500B.